Requirements for the production of storage bunkers

КОНТЕЙНЕРИ ДЛЯ ПОБУТОВИХ ВІДХОДІВ

CONTAINERS FOR HOUSEHOLD WASTE

General technical requirements DSTU 8476:2015

The carrying capacity of the container is calculated based on the nominal capacity (volume) and maximum density (250 kg/m3 – for waste as secondary raw materials; 400 kg/m3 – for household waste and bulky waste; 800 kg/m3 – for repair waste.

The main dimensions of containers include: width, length, height.

The capacity (volume) and carrying capacity of large-sized changing containers for bulky waste (BWW) and their main dimensions are given in the appendix below.

The actual capacity (volume) of the KVV container cannot differ by more than (5-10) %

Metal containers are made from hot-rolled and cold-drawn sheets

structural steel of different thickness and profile.

Assembled units and container parts are bolted or welded in accordance with GOST 8724,

GOST 9150, GOST 1759.0, GOST 5264, GOST 14771, GOST 14776 and GOST 3242.

The protective coating of metal containers can be:

– Paint – according to GOST 9.032, GOST 9.402 and GOST 9.104.

It is permissible to use other types of protective coatings on the surfaces of containers, resistant to the conditions of operation of containers in the fresh air and the aggressive environment of household waste

SAFETY REQUIREMENTS

1. The design of the containers should make it impossible to injure consumers.

2. Containers must be resistant to involuntary overturning.

3. During the operation of the containers, it is not allowed:

– be in the area of operation of the lifting mechanism when lifting and overloading the container

a specially equipped vehicle;

– hold the container with your hands and help the lifting mechanism after hooking the container

lifting mechanism of a specially equipped vehicle;

ENVIRONMENTAL PROTECTION REQUIREMENTS

1 Materials from which the containers are made must be non-toxic, not cause negative effects

impact on the environment and human health.

2 Materials from which containers are made should not stimulate the development of microflora,

must be resistant to disinfectants and temperature changes in the air environment and the aggressive environment of household waste.

3 When using containers, surface water is protected in accordance with SanPiN 4630.

4 During the operation of the containers, the soil is protected in accordance with the State sanitary standards

and rules for maintaining the territories of populated areas.

5 During the operation of containers, waste is handled in accordance with DSanPiN 2.2.7.029.

NOMINAL CAPACITY (VOLUME) AND LOAD CAPACITY OF CONTAINERS AND MAIN DIMENSIONS

| The name of the indicator | Types of containers (by design purpose) | ||

| Open bucket with a vertical back wall | Open bucket with a sloping rear wall | ||

| Capacity, m3 | 5,0 | 7,5 | 10,0 |

| Carrying capacity, kg | 4000 | 6000 | 8000 |

| Width, mm | 1800 | 1900 | 2000 |

| Length, mm | 3000 | 3500 | 4000 |

| Height, mm | 1500 | 1600 | 1700 |

Limit deviations of dimensions +/-15%

All products of the European standard according to DIN 30720-1 are fire-resistant and have an ergonomic design.

The container is designed for loading and unloading storage containers using a hydraulic lifting system such as a portal loader.

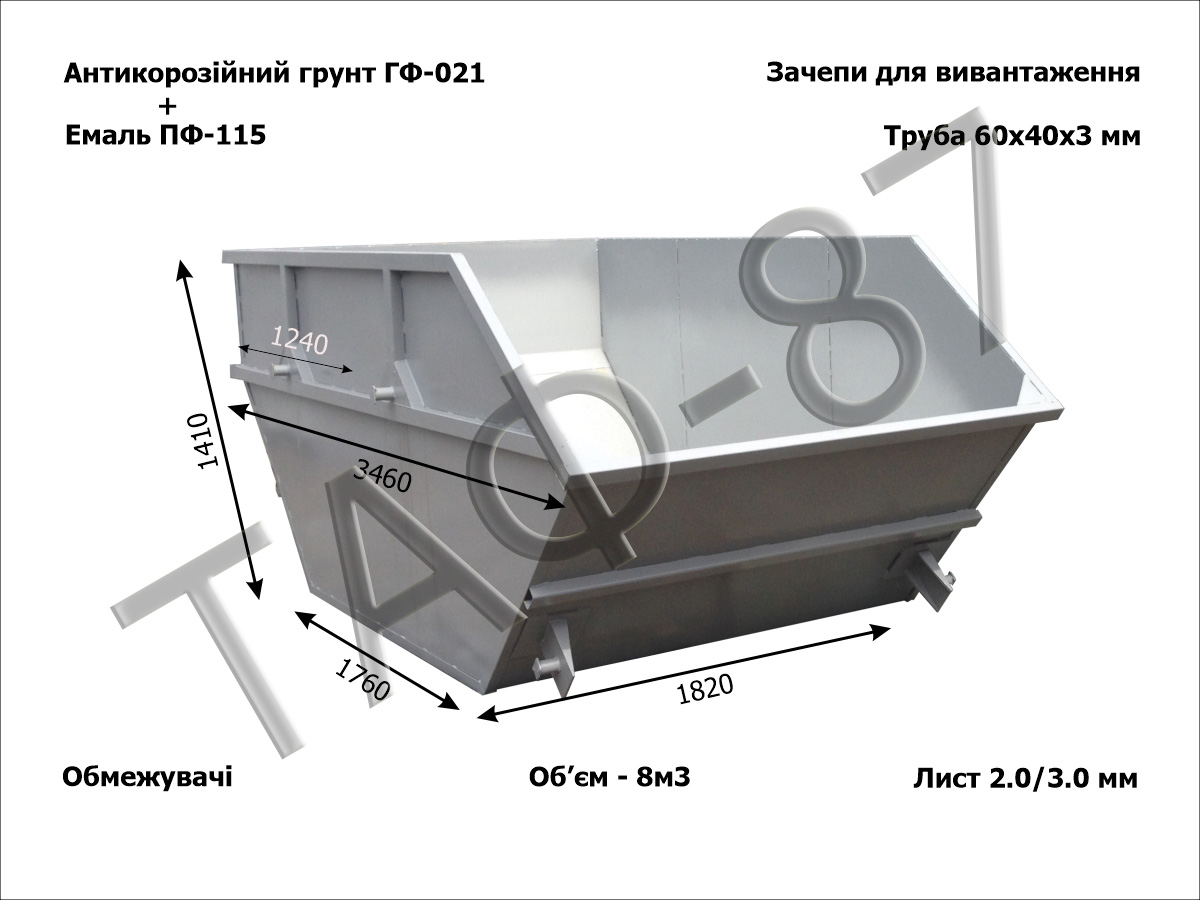

The body of the container is made of sheet metal of various thicknesses of 2 mm or 3 mm, with additional stiffening ribs of sheet metal.

The bottom and front side are also made of sheet metal with a thickness of 2 mm or 3 mm. (customer’s choice)

The edging of the container is welded and the profile pipe 60x40x3 mm.

These are the bins for garbage with a volume of up to 8 m3. and carrying capacity up to 6.0 tons, manufactured by the TAF-87 company.

The hopper for solid waste is primed and painted on all sides, delaying metal corrosion and helping to increase the service life of the container. GF-021 anti-corrosion soil is used. Then it is covered with alkyd enamel PF-115, completely from the outside, the bottom, and the side walls 0.5 meters above the perimeter from the inside, the color of your choice.

The production of containers and painting is carried out at our own technological base. At the TAF-87 enterprise, the storage hopper is produced in the workshop using a sheet bending machine, guillotine, cutting and machining machines, which reduces the number of welding areas and increases the quality of the product. Welding is done semi-automatically, protective coatings are applied with a spray gun.

The TAF-87 enterprise is engaged in the design and manufacture of structures according to individual dimensions (of any configuration).

The products have a 12-month warranty and a long service life.